Equipment List

Our facility is equipped with advanced technology to handle complex manufacturing requirements efficiently.

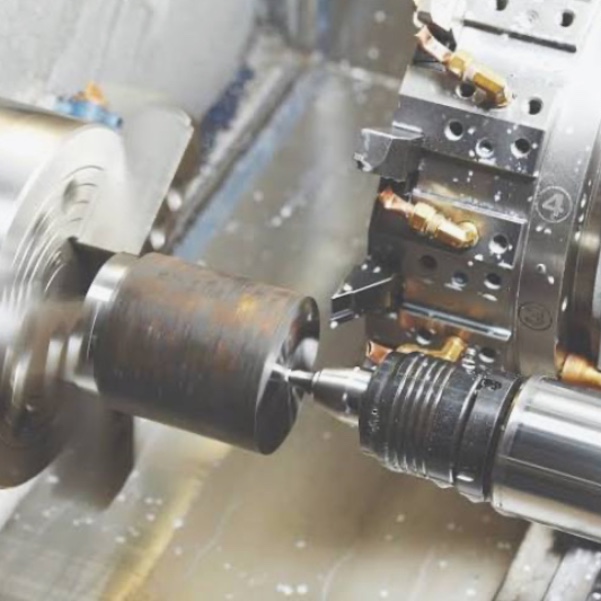

Cnc multi-axis mills and lathes

Our CNC multi-axis mills and lathes deliver high precision and flexibility, enabling us to produce intricate parts with exceptional accuracy.

MiG and tig welders

Our MiG and TIG welders provide versatile welding solutions, ensuring strong and reliable joints for a variety of metals and applications.

Saw

Our precision saws are capable of cutting materials with high accuracy and efficiency, tailored to meet specific project requirements.